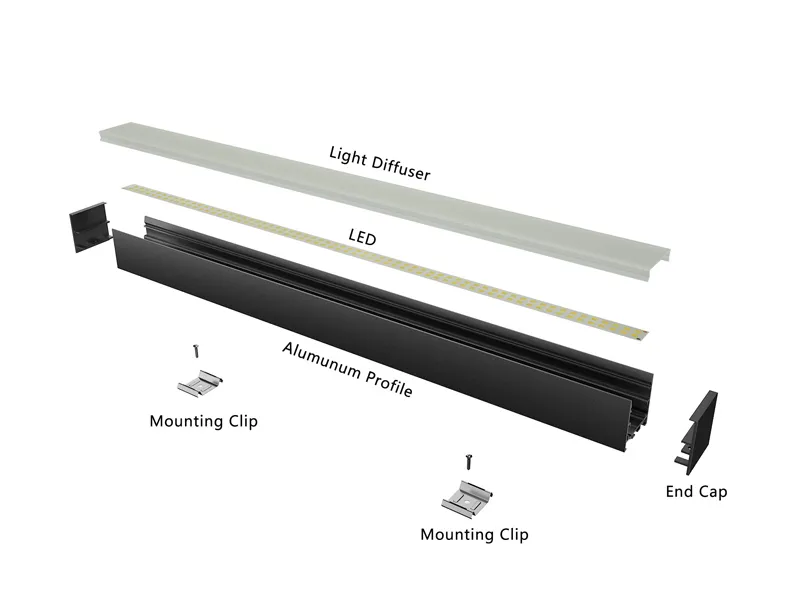

The aluminum profile and LED diffuser are the main parts of an LED profile. The LED diffuser plays the role of guiding LED lighting when it is covered on the top of an aluminum extrusion. However, the LED diffuser determines how much the light is transmitted and the final lighting effect. The production of LED light diffusers is much more complicated than the aluminum extrusion. The material, the technical, and the molding, any of these factors will affect the quality of the LED diffuser.

At present, we mainly focus on producing strip LED light diffusers for LED linear lighting fields. From flat LED strip diffusers to angled, curved, tubes, and pipes, anything that related to lighting is our business. Buying an LED aluminum profile can be easy, but it’s not the same thing with an LED light diffuser. LED diffuser manufacturing is more complicated. TANGOO has many years of experience and advantages in manufacturing LED strip diffusers, which many other LED profile suppliers do not have.

Plastic extrusion factory

Our company set up an extrusion manufacturing plant covering an area of 2,000 square meters years ago. The factory is equipped with 18 production lines for PC and PMMA LED strip diffusers. The equipment and processes of our production lines have been carefully designed and optimized, and our production capacity and quality can be highly guaranteed. We can provide different choices and customization services for all our customers.

Professional plastic extrusion mold designer

Extrusion mold design is one of the most particular parts in the production of plastic products, and professional mold designers are one of the key factors to ensure the efficiency and accuracy of the entire production process. Our mold designers not only have experienced engineering knowledge but also have a deep understanding of the characteristics of plastic materials. They can accurately formulate mold design plans based on our customers’ requests and use advanced CAD technology for precision drawing. Our mold designers can creatively solve the challenges in mold design and ensure optimal mold design performance. Our mold designers also pay attention to material selection, cost control, etc., to provide customized mold design solutions.

Professional plastic extrusion mold department

We have set up a mold-making department in our company. The mold-making department has a skilled and experienced team who are experts in manufacturing various plastic extrusion molds. In the meantime, we have developed our advanced mold production technology and introduced advanced CNC processing machines to produce various high-precision molds. Our professional mold production department gives us a greater advantage than our competitors. And this finally makes us able to efficiently complete any customized production.

Sorts of LED diffusers

We work on many types of LED light diffusers based on PC and PMMA materials. From simple structure-designed strip diffusers to complicated ones. From single-color extruded strip diffusers to co-extrusion strip diffusers. In addition to manufacturing our own designed diffusers, we also produce custom-made LED diffusers for many clients.

Flat-shaped LED diffuser

Square-shaped LED diffuser

Tube-shaped LED diffuser

Curve-shaped LED strip diffuser

Lens LED strip diffuser

Irregular LED Strip diffuser

High-quality PC and PMMA materials

Our extrusion factory mainly produces Polycarbonate and Acrylic material LED strip diffusers. We use high-quality PC or PMMA materials like TEIJIN and BAYER for the manufacturing of LED light diffusers. By using top-brand materials, we ensure that our products meet rigorous standards like UL and ETL. This is also a commitment to all our valued customers. Let our light diffusers be the best solutions for their LED lighting projects.

Conclusion

We can handle intricate designs of PC or PMMA LED strip covers. Our expertise allows us to produce custom light diffusers that meet specific requirements and preferences. We work closely with customers throughout the design and manufacturing process, providing personalized guidance and ensuring the final product surpasses their expectations.