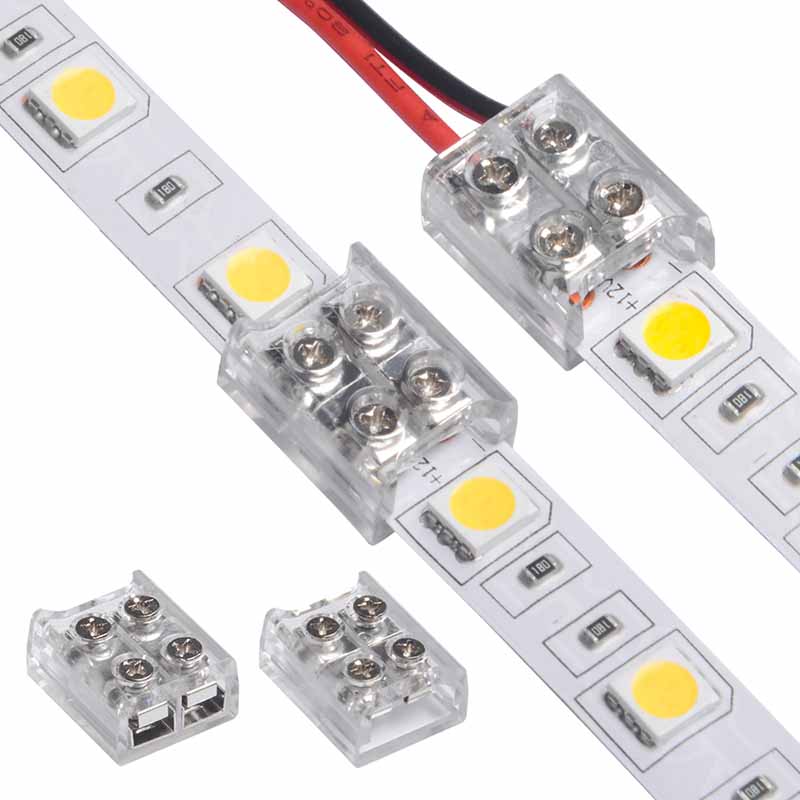

Solderless LED Connector

Solderless LED connectors are small devices that help you join LED strips or connect them to a power supply or a controller by clamping them in place. The connection between the LED strips and connectors does not require any soldering. There is no need to solder the LED strips to the connections.

The solderless LED strip connector is different from a regular soldered connection, which needs a hot iron and a steady hand to produce a solid electrical connection. LED strip solderless connectors are the plug-and-play solution for custom LED strip lighting.

The major part of an LED solderless connector is a strong plastic housing that has a hinged clip that clamps close tightly. There are small metal prongs inside this plastic shell. These prongs are usually composed of copper, which is a great conductor of electricity. When you close the clip, the copper contacts push down hard on the copper pads of your LED strip. This makes a strong connection that powers your lights.

LED solderless connector types

screw fixing

COB connector

Hippo connector

waterproof connector

solderless LED strip connector terms

strip to power

strip to strip bridge

strip to strip

Screw fixing connector specification

Technical Data

COB connector specification

Technical Data

HIPPO connector specification

19.6*12.6*7.7mm

19.6*14.6*7.7mm

19.6*14.6*7.7m

19.6*14.6*7.7m

19.6*17*7.7mm

Technical Data

waterproof connector specification

28*15.5*8.5mm

28*17.5*8.5mm

28*17.5*8.5mm

28*17.5*8.5mm

Technical Data

FAQs about LED strip connectors

What are LED connectors?

LED connectors are small parts that connect LED strip lights to one other, to a power supply, or to other accessories like dimmers or controllers. They don’t need any soldering, and it’s easy to change the length and pattern of LED strip lighting for any project.

What are the different kinds of LED connectors?

The most common types of LED connections are:

Strip-to-Strip connections: These connections link two separate LED strips together so that they can run for a longer time.

Strip-to-Wire Connectors: One end has a connector and the other end has bare wires. This lets you connect your LED strips to a power supply or controller.

Corner or L shape Connectors: These are already formed to assist you simply go around corners and angles without damaging the LED strips.

Pigtail connectors are like strip-to-wire connectors, except they usually contain a plug on the end of the wire that makes it easy to connect to power adapters.

What kind of connector would work best with my LED strip?

The PCB width of your LED strip is the most important thing that decides it. Make sure the connection is clean and the connector’s width is the same as the LED strip’s. You should also think about how many pins the connector has. Four-pin connectors are needed for RGB (color-changing) strips, but two-pin connectors are commonly needed for single-color strips.

How do I pick the proper connector for my LED strip?

Make sure the connection is strong and the connector width matches the strip width. Also, think about how many pins the connector has. Most of the time, single-color strips use 2-pin connectors, whereas RGB (color-changing) strips require 4-pin connectors.

What is the difference between a connector that doesn't need solder and one that does?

With solderless connectors, you just open the clasp or clamp, put in the LED strip, and close it to form a connection. They are perfect for quick, easy projects and for people who don’t like to solder. Soldering is a more difficult and skilled way to make an electrical connection that will last and be very reliable.

Do I need specific connectors for LED strips that are waterproof?

A silicone or tube layer protects the waterproof LED strips. To utilize a conventional connector, you first need to carefully take off this coating from the connection points. Connectors built just for waterproof strips are the finest way to make a connection that is truly waterproof. These connections are usually bigger and have a design that goes through the waterproof coating to provide a strong, sealed connection.

What is the difference between connections for RGB LED strips and single-color LED strips?

The number of pins is the key difference. Single-color LED strips only need two wires (positive and negative), hence they use 2-pin connectors. RGB (Red, Green, Blue) strips feature four wires: one for each color plus a common positive. Because of this, they need 4-pin connectors. It won’t work if you use the wrong kind of connector.

Are LED strip connectors reusable?

Certainly. If you switch your lighting configuration, most solderless “clamp-style” connectors may be opened and closed multiple times, allowing you to recycle them. Be cautious when opening the clasp to prevent breaking it.

What is a COB LED strip connector?

A COB LED strip connector is a special kind of connector that makes a safe electrical connection to a COB (Chip-on-Board) LED strip without soldering. These connections make it easier and quicker to add, install, or connect LED strips.

These are the most common types of COB LED strip connectors.

Strip-to-Strip Connectors: These connect two COB LED strips together so you can make a longer run. They are available in both straight and angled (L-shaped) designs to help you navigate around corners.

Strip-to-Wire Connectors: These connectors link a COB LED strip to a power supply or extension wires. The LED strip is held in place by one end of the connector, while the other end has wires that can be plugged into a controller or power source.

There are also T-shaped and X-shaped connectors that can be chosen for complicated lighting connections.

Do I need to worry about the voltage and amperage across my connectors?

Most basic LED strip connectors can handle the normal voltage (12V or 24V) and amperage of typical LED strips, but it’s always a good idea to check the requirements. If you want to run very long lengths of high-power LED strips, ensure your connectors can handle the total current so they don’t overheat.

My connector is getting hot. Is this normal?

No, a connector ought not to get particularly hot. Should it happen, it indicates either a weak connection or an excessive electrical current demand. Immediately cut off the power, then examine your connections and the LED strip power draw. It can be a fire risk to use a connector not rated for the amperage of your strips.

Can I connect LED strips from two different brands together?

Yes, as long as the key specs match up. Check three things before you buy a connector: the strip width (e.g., 10mm), the voltage (must be the same, like 12V or 24V), and the number of copper pads at the cut point (2 pins for single color, 4pins for RGB, etc.). If all those match, you can connect different brands without a problem.

Will a connector fit inside an aluminum channel with a diffuser cover?

Most standard “clamp” connectors are too bulky and will prevent the plastic diffuser cover from snapping on correctly. If you must use a connector, look for special “slim” or “channel-friendly” versions designed for this purpose.

What tools do I actually need to use solderless connectors?

You don’t need any special tools to use solderless connectors, which is great. You only need a decent pair of scissors to make a clean, straight cut along the designated cut line on the LED strip. That’s all.

Does the number of LEDs on the strip per meter matter for the connector?

The number of LEDs per meter (for example, 60 LEDs/m vs. 120 LEDs/m) does not affect the type of connector you need. The connection pads at the cut places are all the same. Just make sure the connector fits the strip’s width and number of pins.